Services

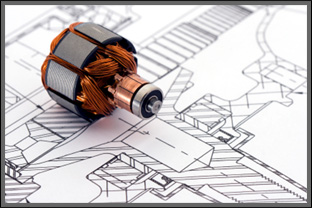

Besides our great on-line and live over the phone service, our facility offers a full range of in-house services which cater to all things laundry. Our expertise ranges from motor rewinds, mechanical repairs, pump repairs and also machining.

As motors arrive to Laundry Motors, they are rapidly evaluated, customers are contacted with findings, and a free estimate is provided at that time.

- Motor Rewinds – Motors which are physically burnt, developed a short or damaged by water will need to be rebuilt by removing damaged coils and replacing them with fresh coils rewound to factory specifications. The process start to finish takes two to three business days.

- In-House Testing – Testing and diagnostics are done in a “while you wait” fashion. This will eliminate problems in question and save customers time, testing of motors and pumps at our facility results in a 100% ruling.

- Mechanical Repair – Repairs are done on a first come, first serve basis. Fortunately we keep all major brand laundry motors and pumps stocked on the shelves for immediate exchange, thus eliminating downtime.

- Pump Repair – We service and repair both submersible and circulating pumps. We also carry all parts necessary for the do-it your-selfer.

- Machining – All machining and welding is done in-house. We machine custom bushing sleeves found in our shaft save kits, as well as other obsolete parts. We offer welding and machining on worn washer drum shafts as well, returning the bearing seats to their original state.